Vacuum Insulation Tech & Eco-Friendly Coating Revolution

From Lab to Production Line: The Technological Breakthrough Battle in the Thermos Industry

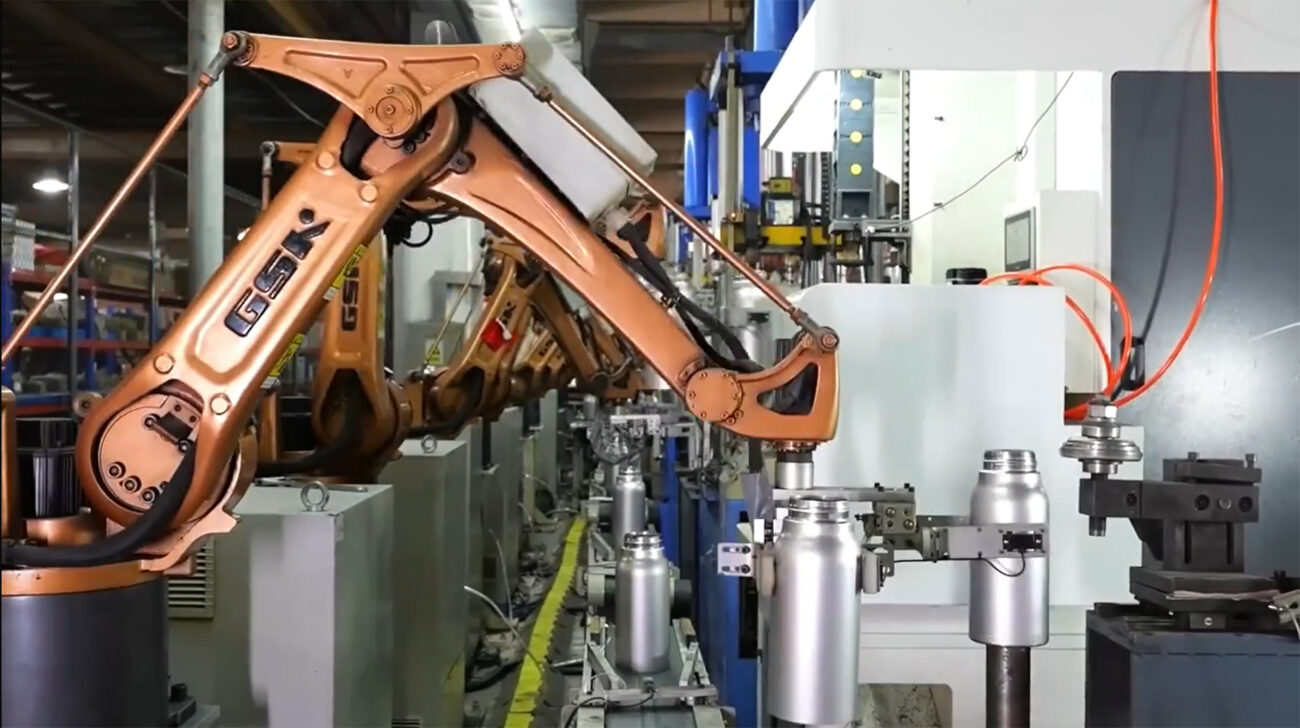

Driven by "Dual Carbon" goals and health-conscious consumption, China's thermos industry is undergoing a core technology upgrade. A recent report from the China National Hardware Association reveals that thermoses with dual tech of vacuum insulation & eco-coating reached 38% market penetration in 2023, commanding a 45% price premium over traditional products. This industrial revolution, powered by physics and material science, is reshaping the global insulated container market.

[Technology Decoding] Vacuum Insulation: Commercializing Physics Laws

Thermodynamic Triple Defense System

Vacuum insulation blocks heat transfer via three pathways:

Heat Conduction: 0.01Pa high vacuum between double-layered stainless steel reduces thermal conductivity by 98% (SGS data).

Heat Convection: Vacuum eliminates gas molecule movement, minimizing convection.

Heat Radiation: Copper plating on the inner liner reduces radiant heat loss by over 60%.

Japanese Thermos lab tests show vacuum structure boosts insulation 3-7x. Increasing vacuum from 10Pa to 0.1Pa drastically improves 24-hour heat retention for 98℃ water from ΔT=35℃ to ΔT≤12℃.

Process Precision: Line of Life and Death

Vacuuming temperature must be stable at 450±5℃ to prevent metal deformation.

Helium mass spectrometer leak detectors reach 5×10^-12 Pa·m³/s precision, ensuring a decade of vacuum retention.

A Zhuhai company uses magnetron sputtering coating, cutting radiant heat loss from 15% to 7%.

Wholesale glass cup

Titanium kettle 1L large capacity

Titanium coated stainless steel water bottle

Titanium alloy thermos

Stainless steel food can

Sealed Insulated Lunch Box

Food Thermos with Spoon

Food thermos

[Process Revolution] Water-Based vs. Solvent-Based Paints: A Molecular War for Health

VOC Emission Comparison (Data: Institute of Materials Science, Chinese Academy of Sciences)

| Indicator | Water-Based Paint | Traditional Solvent Paint | Reduction |

|---|---|---|---|

| Benzene Release | 0.02mg/m³ | 3.8mg/m³ | 99.5% |

| Heavy Metal Content | Not Detected | 0.6mg/kg | 100% |

| Drying Energy | 45kW·h/ton | 82kW·h/ton | 45% |

Performance Breakthroughs

- Wear Resistance: New water-based nano-paints pass 5000 steel wool rubs (ASTM D4060).

- Color Fastness: UV-cured water-based paints reach Level 8 (ISO 105-B02).

- A Zhejiang company's "low-temperature self-crosslinking" tech boosts paint film hardness from 2H to 4H.

[Industrial Implementation] Economic & Ecological Benefits of Tech Upgrade

Cost-Benefit Analysis (Annual output of 2 million thermoses)

| Item | Traditional Process | Eco-Upgrade Plan | Annual Savings |

|---|---|---|---|

| Hazardous Waste Disposal | ¥780,000 | ¥120,000 | ¥660,000 |

| Work Injury Costs | ¥230,000 | ¥15,000 | ¥215,000 |

| Export Tax Rebate | - | +9% tax rate | ¥3,600,000 |

Consumer Market Response

After adopting water-based spraying, Zwilling J.A. Henckels’ Tmall flagship store saw a 72% drop in negative reviews (mainly odor complaints).

[Technology Foresight] Material Innovation Opens Imagination

Aerospace Tech Transfer

Aerogel composite vacuum layers extend insulation to 36 hours (International Space Station tech).

Phase-change energy storage materials enable smart temperature control in 6℃-60℃ range.

Bio-based Coating Breakthroughs

When thermodynamics formulas meet chemists’ molecular models, the traditional thermos category is unleashing astonishing technological momentum. Innovations from precise vacuum control to water-based resin molecular reconstruction are redefining insulation standards and quietly changing manufacturing’s carbon footprint curve. Behind every thermos compliant with EU ECMA 342-2024, lies a grand tech narrative about energy efficiency and human health.